How Digital Manufacturing Is Reshaping Thermoforming Economics

The thermoforming industry is experiencing a fundamental shift. Digital technologies are making it economically viable to produce smaller batches of customized parts without the traditional cost penalties that once made low-volume production impractical.

Three converging trends are driving this transformation: the ability to customize parts without expensive tooling changes, growing demand from industries that need specialized solutions, and manufacturing processes that eliminate waste while accelerating time-to-market.

Customization Without the Traditional Cost Premium

Digital design tools and advanced manufacturing techniques have fundamentally changed the economics of customization. What once required expensive mold modifications and lengthy lead times can now be accomplished through digital iteration and rapid tooling methods.

Medical device manufacturers are seeing the most immediate benefits. A diagnostic equipment housing that once required standardized dimensions to justify tooling costs can now incorporate patient-specific ergonomics or facility-specific mounting configurations. The design exists digitally until production begins, allowing modifications without the traditional penalty of scrapped tooling.

In heavy equipment applications, this translates to part variations for different machine configurations without maintaining separate inventories. An agricultural equipment manufacturer can produce cab components with region-specific features—different HVAC configurations for hot climates versus cold, varying control panel layouts for different operator preferences—all from the same core design platform.

Industries Driving Increased Demand

Healthcare applications extend beyond medical devices into furniture and environmental surfaces. Hospital bed components, imaging equipment housings, and diagnostic instrument casings all benefit from materials that resist harsh disinfectants while maintaining their appearance through years of repeated cleaning. The COVID-19 pandemic accelerated this trend, as facilities sought materials that could withstand aggressive cleaning protocols without degrading.

These industries share a common requirement: they need parts that perform specific functions under demanding conditions, often in quantities that don't justify traditional high-volume manufacturing approaches.

Manufacturing Efficiency Through Digital Integration

The waste reduction story in thermoforming deserves closer examination. Traditional sheet metal fabrication generates substantial scrap material—offcuts, trimmings, and pieces too small for secondary use. Thermoforming, particularly when integrated with digital design tools, allows more precise material utilization.

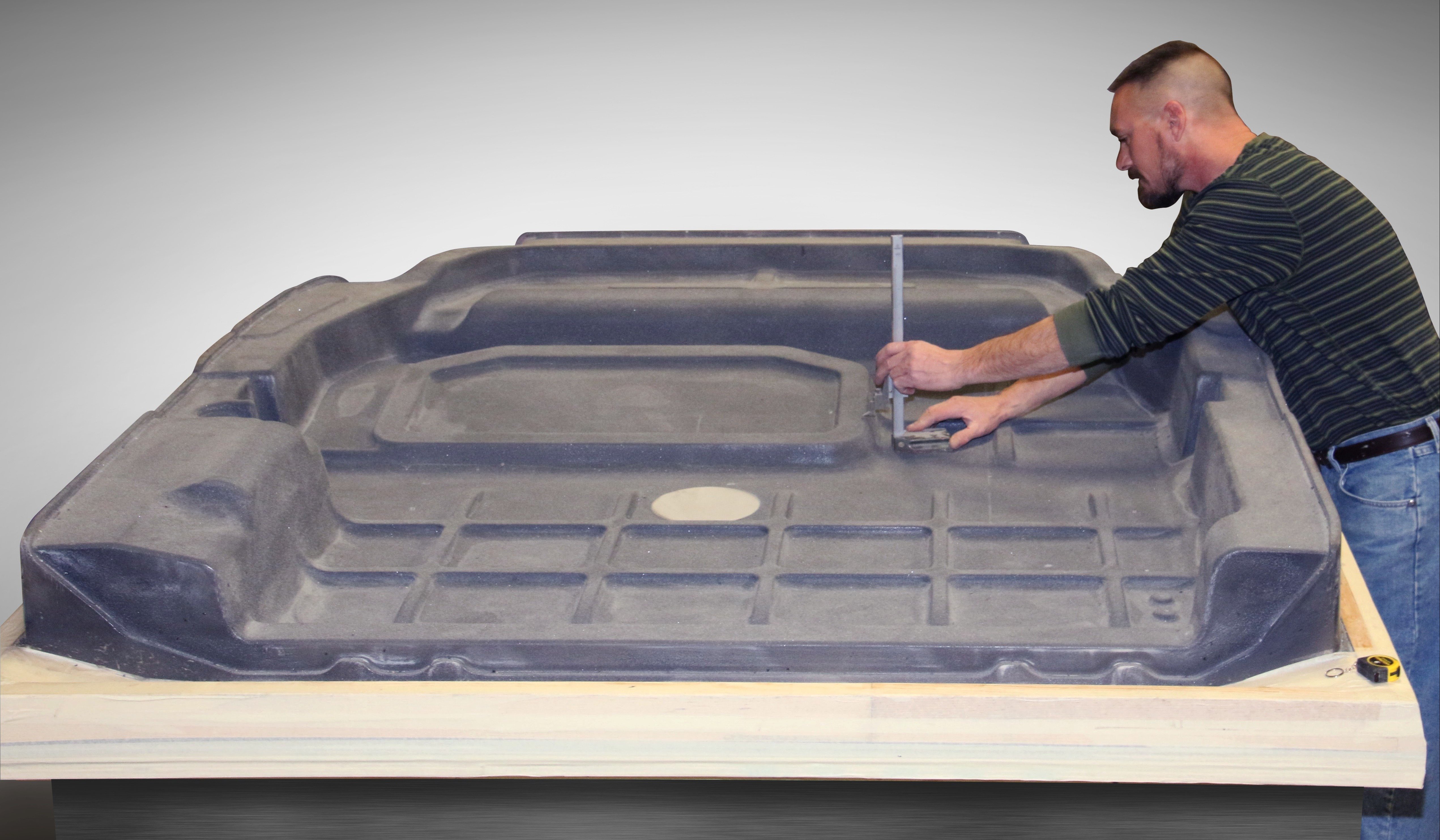

Consider a heavy equipment manufacturer producing a large belt guard. The original steel fabrication required multiple welded pieces, each cut from larger sheets with inevitable waste. A thermoformed replacement uses a single sheet formed to final shape, with trim pieces often returnable to the material supplier for reprocessing into future sheets. The material loop closes in ways that weren't economically feasible with metal fabrication.

Lead time compression represents another significant advantage. 3D printing and CNC machining enable prototype tooling in weeks rather than months. A medical device company can evaluate form, fit, and function with actual production-intent materials before committing to final tooling. An agricultural equipment OEM can test belt guard designs in field conditions, gather operator feedback, and refine the design—all within a traditional prototype timeline.

This rapid iteration capability changes the risk profile of new product development. Rather than front-loading extensive analysis to avoid costly tooling changes, manufacturers can test physical prototypes, gather real-world data, and refine designs based on actual performance rather than predicted behavior.

What This Means for Product Development

The convergence of these trends creates new possibilities for how manufacturers approach component design. Parts that were once over-engineered to accommodate multiple use cases can now be optimized for specific applications. Features that required costly secondary operations can be incorporated during the forming process. Assembly steps can be eliminated by integrating multiple components into single formed pieces.

A transit bus manufacturer recently redesigned interior panels by consolidating what had been three separate stamped metal pieces—each requiring its own tooling, finishing, and assembly—into a single thermoformed component. The weight reduction improved fuel efficiency, the simplified assembly reduced labor costs, and the integrated design eliminated potential noise and vibration issues at panel joints.

Material science advances complement these manufacturing capabilities. High-impact polycarbonates, chemical-resistant ABS formulations, and antimicrobial additives allow thermoformed components to meet performance specifications that previously required metal or fiberglass. The material itself becomes part of the solution rather than a compromise.

Practical Considerations for Implementation

Organizations evaluating thermoforming for current metal or fiberglass components should consider several factors beyond simple cost comparison. Part geometry matters—components with complex curves, varying wall thicknesses, or integrated features often prove more suitable for thermoforming than simple flat panels. Production volume sweet spots typically range from dozens to thousands of units annually, though this varies significantly by part size and complexity.

Material selection requires careful attention to the operating environment. A housing exposed to direct sunlight in Arizona needs different UV resistance than one operating indoors. Chemical exposure from cleaning agents, operating fluids, or environmental contaminants affects material choice. Impact resistance, temperature range, and regulatory requirements all factor into the material specification.

Tooling strategy should align with production expectations. Wood or composite tooling serves well for prototype evaluation and initial production runs. Aluminum tooling suits longer production runs where dimensional consistency and surface finish justify the higher initial investment. The tooling decision affects both upfront costs and long-term part consistency.

Looking Forward

The digital transformation of thermoforming isn't about replacing existing manufacturing methods wholesale. Metal fabrication, injection molding, and fiberglass production all remain viable for their optimal applications. What's changing is the economic calculation for mid-volume, customized components where traditional methods carried cost penalties that often forced design compromises.

Manufacturers now have options that didn't exist five years ago. Design changes that once triggered expensive tooling modifications can be implemented digitally. Custom features that required separate SKUs and inventory management can be produced as needed. Components that were standardized across product lines to amortize tooling costs can be optimized for specific applications.

The question isn't whether digital manufacturing will continue reshaping thermoforming capabilities—that trajectory is clear. The relevant question for manufacturers is whether their current approach to component design and production is optimized for these new capabilities, or whether they're applying outdated assumptions about customization costs and production minimums to problems that now have different solutions.