How Thermoforming Enabled a Solar Racing Team's Vision for a Clear Aerodynamic Windshield

When the Badger Solar Racing team approached Plastic Components Inc. (PCI) with an ambitious request to thermoform a fully clear windshield dome for their solar-powered race car, they presented a unique combination of challenges that would test the limits of large-scale clear plastic manufacturing.

*Check out the video of INDOT and Purdue partnership testing limitless-range transportation system.

The Engineering Challenge Behind Solar Racing

The University of Wisconsin-Madison's Badger Solar Racing team designs, builds, and races solar-powered vehicles in some of the most demanding endurance competitions in North America. Their main events include the Formula Sun Grand Prix, a grueling 3-day track race where teams compete to complete the most laps, and the biennial American Solar Challenge, a cross-country endurance race that pushes both vehicles and teams to their limits.

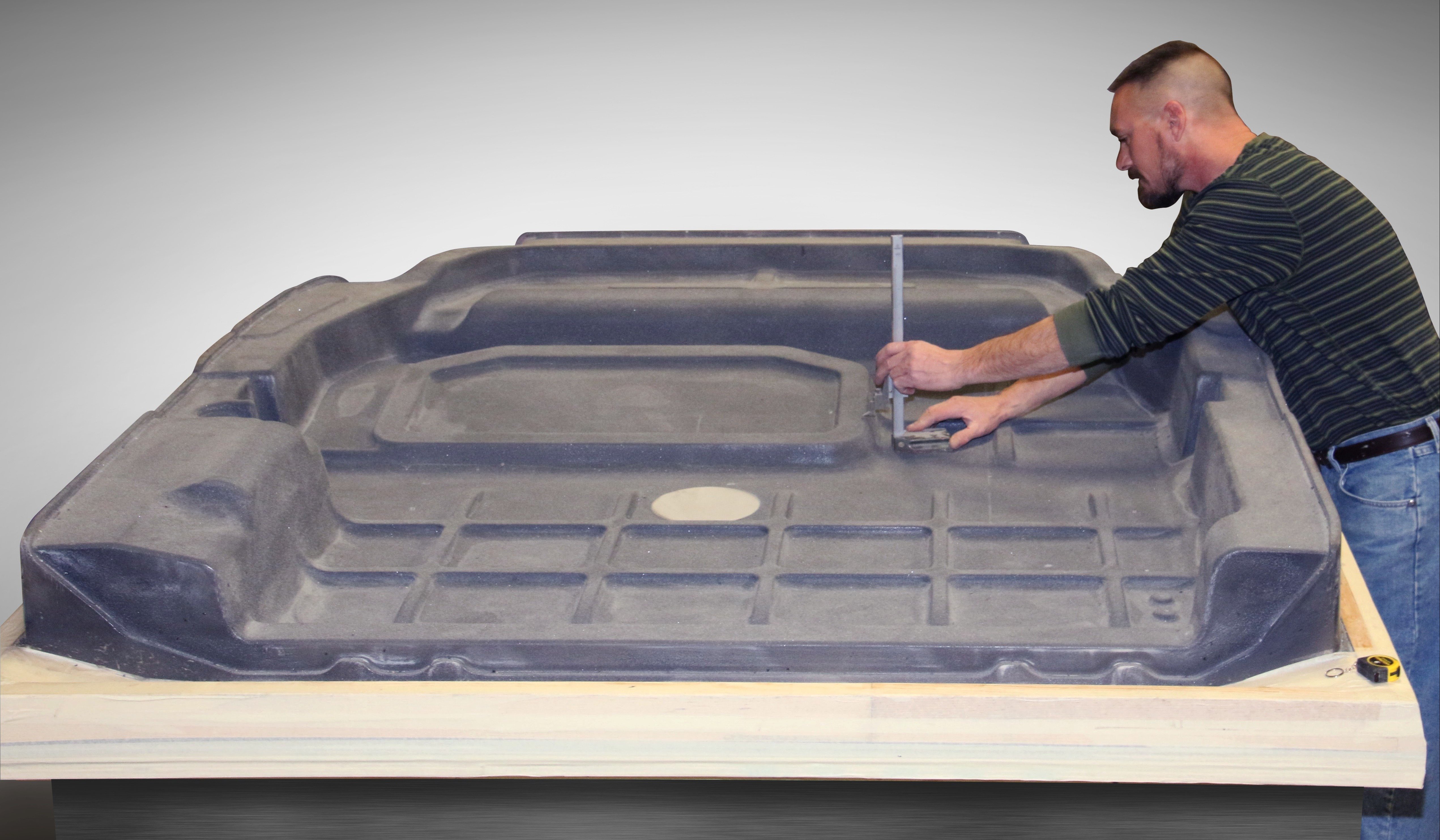

The team's latest vehicle measures approximately 6 meters long by 1.5 meters wide by 1 meter high, with a fully carbon fiber aeroshell manufactured entirely in-house by the 80-member student organization. While most competing teams opt for carbon fiber windshields with small polycarbonate viewing windows, Badger Solar Racing had a different vision.

Maanik Chawla, the team's Industry Relations Team Lead, explains their approach: "Our goal was to manufacture a fully thermoformed windshield. By doing this, we saved a lot of time vs had we gone and tried to do a carbon fiber manufacturing process and add in polycarbonate windows."

Why Most Teams Avoid Clear Windshield Domes

Creating a fully transparent windshield dome for a solar racing vehicle presents several technical obstacles that explain why few teams attempt this approach. The windshield must maintain perfect optical clarity while conforming to complex aerodynamic curves essential for competitive performance. At the same time, the part must be large enough to provide adequate driver visibility while integrating seamlessly with the carbon fiber body.

The traditional carbon fiber windshield approach allows teams to avoid these complications, but it comes with trade-offs in weight, visibility, and manufacturing complexity when polycarbonate windows are added separately.

Thermoforming's Advantages for Large Clear Components

PCI's expertise in large-scale thermoforming made the Badger Solar Racing project feasible where other manufacturing methods would have fallen short. Thermoforming excels at producing large, complex-curved parts with excellent optical properties while maintaining cost-effective tooling compared to alternatives like injection molding or composite layup processes.

The process allows for precise control over wall thickness distribution, which is critical for maintaining optical clarity across varying curvatures. Unlike multi-piece assemblies, thermoforming produces a single, seamless component that eliminates potential leak paths and reduces assembly time.

Alexander Nealy, Badger Solar Racing's Mechanical Director, noted the quality of the finished product: "We got a really good final product that we need to do minimal work to get onto our car."

Collaborative Engineering Approach

Rather than providing rigid specifications, the Badger Solar Racing team focused on performance outcomes, challenging PCI to deliver successful thermoforming of the required shape without bubbles or surface defects while maintaining excellent optical clarity. This approach allowed PCI's engineering team to optimize the manufacturing process for the specific requirements.

Kyle Ma, the team's President, recognized the value of this collaboration: "The PCI staff was very insightful about the thermoforming process, and we saw that in our final product."

The partnership extended beyond pure manufacturing support. Maanik Chawla, Industry Relations Team Lead, highlighted the personal attention the team received: "PCI was extremely helpful and generous in helping us. Outside of actually agreeing to do the thermoforming for us, the people were all extremely nice and were fun to interact with. They even gave us recommendations for things to do around Elkhart and places to go on the way back."

Technical Success in Complex Geometry

The windshield dome required PCI to overcome three significant technical challenges that converged. The large size pushed the boundaries of forming envelope capabilities, while the requirement for perfect optical clarity demanded precise temperature control and contamination-free processing.

Most critically, the complex aerodynamic curvature required careful material flow management to prevent thinning in critical areas while maintaining uniform optical properties.

Successfully thermoforming large, clear parts requires expertise in material selection, heating profiles, and managing forming pressure. The dome shape presents particular challenges because material must stretch significantly more in some areas than others, potentially creating thickness variations that affect optical quality.

Cost-Effective Innovation for Student Teams

For student racing teams operating on limited budgets, thermoforming's lower tooling costs compared to injection molding or complex composite tooling make ambitious projects feasible. The process enables rapid prototyping and modifications without the substantial capital investment required for steel tooling or complex composite mandrels.

This cost advantage becomes particularly important for educational programs where learning and iteration are as valuable as the final product. Teams can explore innovative designs without prohibitive upfront investments in manufacturing tooling.

Looking Ahead to Competition

We provided our services and the finished project pro bono because we love to push the limits of what we can do and we appreciate young engineers learning their field and want to encourage them along the way!

With their new windshield successfully integrated, Badger Solar Racing aims to compete in both the Formula Sun Grand Prix and American Solar Challenge 2026, targeting podium finishes in both events. The fully clear windshield dome represents more than just a technical achievement—it demonstrates how advanced manufacturing processes can enable student innovation in competitive engineering.

The partnership between PCI and Badger Solar Racing illustrates how thermoforming expertise can solve complex engineering challenges while supporting educational initiatives. When teams push the boundaries of what's possible in student competition, manufacturers like PCI help turn ambitious visions into racing reality.

For engineering teams facing similar challenges with large, complex clear components, thermoforming offers a proven path from concept to competition-ready parts. The combination of design flexibility, cost-effectiveness, and optical quality makes it particularly well-suited for applications where traditional manufacturing approaches fall short.